Electricide® is the brand name for the Dioxide Pacific electrochemical chlorine dioxide generators

There are many methods for generation of chlorine dioxide and each has pro’s and con’s. Some methods involve chemical reactions with two or more chemicals.

It would be simpler and safer to generate chlorine dioxide from one chemical, if it was possible. Yes, it is possible. Our Electricide® generators generate chlorine dioxide from one chemical: Electricide-P1 and electricity.

Obtain Technical Info & Quotation

What are the Pros of the electricide® generator?

- One precursor chemical

- High chlorite conversion = low running cost

- High purity chlorine dioxide product, either gas or solution

- Chlorine free chlorine dioxide

- Multiple point dosing capability. Inbuilt control for 3 dosing pump, 3 analyzers and control methods: Flow Paced, PID, FPRT (Flow Paced Residual Trim), Manual

- Lower safety risk than other methods

- Neutral pH chlorine dioxide solution generated = low corrosion potential

- Long life electrochemical cell, no replacement cartridges = low ongoing maintenance cost

- Production of 10% sodium hydroxide by-product

Our generators are CE marked for operation in Europe

What are the Cons of the electricide® generator?

- Higher capital cost than equivalent capacity 2-chemical or 3-chemical generators.

- Capital cost is only one part of the cost equation. Lifetime cost of ownership is more pertinent. Chemical running cost for the electricide® generator is generally significantly less than equivalent capacity 2-chemical and 3-chemical generators. Therefore, lifetime cost of ownership for the electricide® generator is much lower. The higher capital cost is forgotten after 1-2 years. Why get stuck with a generator that costs you more and more every year?

- Production of anolyte waste and hydrogen.

- Anolyte waste contains chlorine dioxide, chlorite, chlorate and chloride. It can be neutralised with catholyte and safely discharged to sewer.

- Larger physical size than equivalent capacity 2-chemical or 3-chemical generators

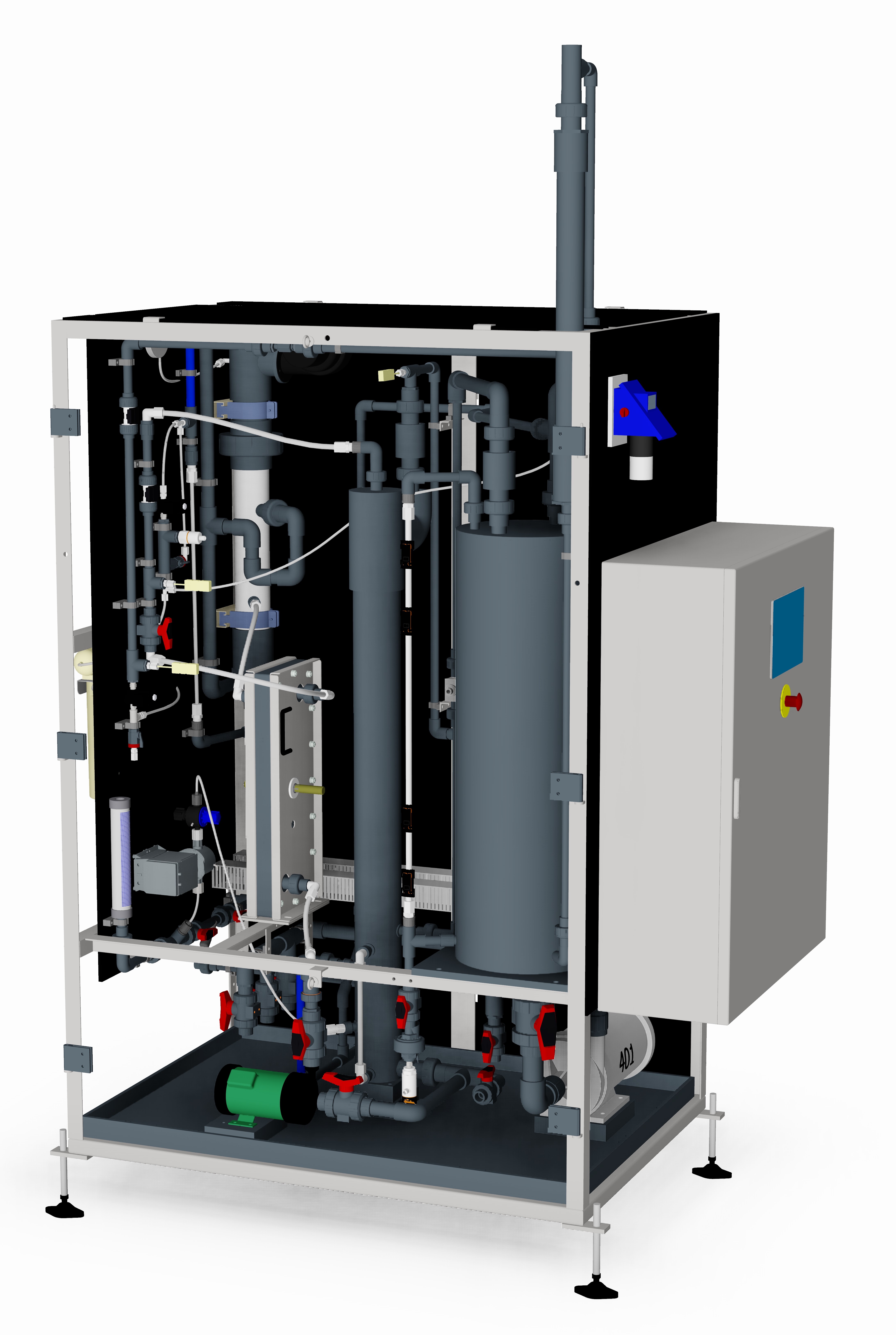

- The electricide® generator is skid mount and has everything included for generator operation within the skid.

- Lower chlorite conversion than 3-chemical and chlorine gas-chlorite generators

- Electricide® generator conversion is up to 80% (temperature dependant). 3-chemical generators can achieve 95% conversion and chlorine gas-chlorite conversion can be 95-98%. Unfortunately, 3-chemical generators require storage and handling of 3 chemicals (instead of 1 for the electricide® generator) and chlorine gas-chlorite generators require storage and handling of chlorine gas with its inherent safety risks.

The Electricide® chlorine dioxide generators utilise one chemical – Electricide-P1 and electrical power to produce 99.5% pure chlorine dioxide. The generators come in two forms: “S” type generators produce chlorine dioxide as a 2,000 ppm solution, stored in a level controlled solution tank, ready for accurate dosing with metering pumps to multiple dosing points. The “G” type generators produce chlorine dioxide gas which can be safely dosed into a single dosing point. “G” type generators are typically used in cooling towers and potable water treatment plants.

Chlorine Dioxide Generation Reactions:

① Anode (oxidation): ClO2– → ClO2 + e–

② Cathode (reduction): 2H2O + 2e– → H2 + 2OH–

① + ② (combined) 2ClO2– + 2H2O → 2ClO2 + H2 + 2OH–

Take a look at a video explaining how the CDEB generator operates ![]()

The key benefits of the Electricide® generator are the use of only one precursor chemical, highest safety and lowest running cost. Another important feature is remote internet access for validation and troubleshooting. For a full list of features and benefits, please download the CDE Electrochemical Chlorine Dioxide Generator Brochure

Electricide CDE Electrochemical Chlorine Dioxide Generator Series brochure (313.0 KiB)

Electricide CDE Electrochemical Chlorine Dioxide Generator Series brochure (313.0 KiB)

How is chemical supplied?

Electricide-P1 can be supplied in 200L (55 Gal) drums or 1,000L (US 330 Gal) IBC’s (totes). The IBC (tote) installation can involve a fiberglass or HDPE spill containment bund which stores chemical in a safe manner, making chemical handling and changeover easy, without operator chemical exposure.

Chlorine dioxide systems can be installed in dedicated plant rooms, skids for transportation to remote sites or in portable buildings.

The use of chlorine dioxide is limitless. However, some widely used applications include the following:

- Potable water disinfection

- Secondary disinfection of water entering healthcare facilities

- Beverage industry process water disinfection

- CIP sanitisation as a replacement for peracetic acid

- Milk condensate (cow water) disinfection for re-use

- Water used for irrigation in greenhouses

- Waste water disinfection

- Thermal energy storage (TES) water

- Disinfestation of plant pathogens (phytophthora, pythium) for nursery irrigation water

- Vegetable and fruit washing

- Food industry process water disinfection

- Membrane (RO, NF, UF) sanitization

- Iron and manganese oxidation

- Cooling tower disinfection for Legionella destruction

- Cooling system macro and micro fouling control for fresh water and sea water circuits

Please see our Systems page for more information on chlorine dioxide systems we provide.

Fabrication

Fabrication