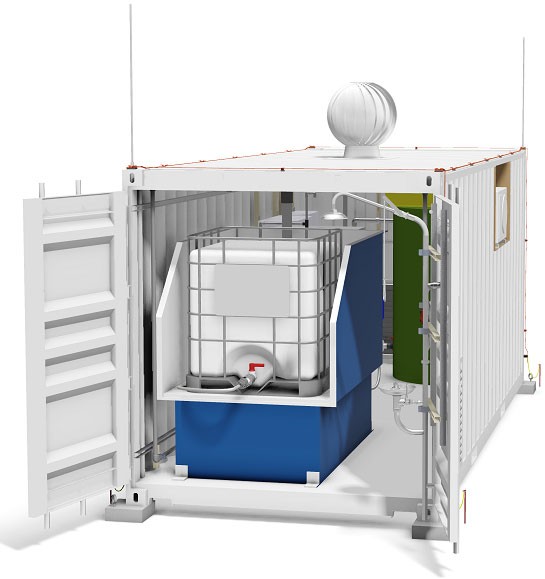

Dioxide Pacific provides sodium hypochlorite dosing systems in package formats which can include bulk chemical storage tanks, chemical bunding, tanker unloading areas, metering pumps, chlorine residual analysers, electrical control panels with site installation and commissioning. Some typical examples are highlighted below.

The old system was removed and replaced with a sodium hypochlorite dosing plant. Dual IBC chemical tanks (duty and standby) were installed in fibreglass IBC bunds. Chemical is delivered and placed by forklift into the IBC bund. Chemical dosing equipment is mounted on an HDPE backboard which is also mounted to the scrubber outside wall. Chemical dosing lines are run through the wall to the scrubber recirculation line. Chlorine residual is controlled via redox measurement and an auto-tune PID controller. pH control is also included with caustic dosing to maintain pH at around 8.0 and ORP at 750 mV. Conductivity of the scrubber liquor is monitored and controlled via an automatic bleed valve. The complete system was designed, supplied and installed by Dioxide Pacific. It has achieved its aim of reducing operator involvement with chemical handling and increased reliability and therefore odour complaints.

Sodium hypochlorite is dosed with duty and standby dosing pumps using an auto-changeover timed sequence. Chlorine residual in the water is monitored using a residual analyser and controlled to a set point of 1 ppm.

The skid is made from HDPE and FiberStrut for chemical resistance and is assembled complete mechanically and electrically prior to delivery.

View a 3D presentation of this plant.

For more information on sodium hypochlorite dosing systems or to obtain a quotation, please complete the feedback form on our Contact page.

Fabrication

Fabrication